How and what are solar panels constructed of?

PRwire360

31 Dec 2022, 00:12 GMT+10

Many marvels at how solar photovoltaic cells can be efficient and affordable while delivering green energy. Answering that question requires knowledge of solar energy, manufacturing, and parts. Monocrystalline, polycrystalline, and amorphous silicon panels dominate the market. We'll discuss solar cell manufacturing and solar panel parts in this article.

Solar panels' materials?

Silicon is a key component of solar panel semiconductors, which generate electricity from solar energy. However, solar panels are more than just their cell components. Six components make a solar panel. Silicon solar cells, a metal frame, glass, glass sheet, 12V wire, and bus wire are included. If you are DIY-minded and intrigued about solar panel materials, you may desire a hypothetical "ingredients" list to make one. Solar panel parts:

Silicon solar cells

The photovoltaic effect powers silicon solar cells. Silicon cells, soldered in a matrix between the glass panels, interact with the thin glass wafer sheet to form an electric charge.

Metal frame (typically aluminum)

The metal frame of a solar panel protects it from weather and other dangers and helps attach it at the proper angle.

Glass sheet

The thin glass case layer protects the silicon solar cells inside.

A conventional solar panel protects silicon photovoltaic (PV) cells with a glass shell at the front. The panel has a protective back sheet and an insulating casing under the glass to reduce heat dissipation and dampness. Temperature rises reduce efficiency and solar panel output, making insulation crucial. Thus, solar PV makers must work harder to capture light without overheating the device.

12V wire

A 12V wire regulates energy transfer into your inverter, improving solar module performance and sustainability.

Bus wire

Bus wires parallel silicon solar cells. Bus wires are thick enough to conduct electrical currents and coated for simple soldering.

Solar panel production: how?

Solar panels consist of monocrystalline or polycrystalline silicon solar cells soldered together and sealed under anti-reflective glass. Photovoltaic cells generate electricity when light hits them. Solar panels have five main steps:

1. Make solar cells.

2. Solder solar cells into a panel.

3. Install backsheet, front glass, and frame.

4. Install a junction box

5. Quality testing

1. Solar cell construction

Solar panels have solar cells. Silicon ingot for p- or n-type solar cells is crystalline silicon with gallium or boron. Cells conduct electricity with phosphorus. An anti-reflective layer is applied on thin silicon ingot sheets. To channel electricity, cells are slit.

2. Solder solar cells into a panel.

Soldering connects solar cells after phosphorous charges silicon wafers. Solar panel size determines the number of cells soldered together. Commercial projects use 72-cell panels, while 60-cell panels are normal.

3. Install backsheet, front glass, and frame.

A plastic back sheet protects solar cells. Next, a thin glass layer is placed over the solar cells to filter sunlight. EVA glue holds these components together (EVA). A metal frame secures these components to roof clamps.

4. Install junction box

The junction box protects a solar panel's wiring to prevent energy from reversing direction. When solar panels aren't producing electricity, they'll try to consume energy. Solar panels work because the junction box prevents electric flow reversal.

5. Quality testing

Each solar panel is evaluated under Standard Test Conditions (STC) to ensure it meets the manufacturer's technical specification sheet's outputs, efficiencies, and other claims. Panels are flash tested at 1000W/m2, 25C cell temperature, and 1.5g air mass. If it passes, ship and installs the solar panel.

How do Solar panels work?

Silicon cells are key components of solar photovoltaics. Silicon, atomic number 14 on the periodic table, is a conductive nonmetal that can turn sunlight into energy. The light activates electrons in a silicon cell, generating electricity. Photovoltaic effect.

Silicon cells cannot power your home. The solar cell's electrons escape through a metal shell and wiring. Thin film solar panels use monocrystalline, polycrystalline, or amorphous silicon.

Solar panel production and kinds

Monocrystalline solar panels are silicon wafers made from one silicon block. Solar panels are made by cutting silicon wafers. Monocrystalline silicon cells outperform polycrystalline and amorphous solar cells. Monocrystalline wafers are more labor-intensive to make than polycrystalline cells. Hence they cost more. Monocrystalline cells, like SunPower's premium panels, are black.

Polycrystalline solar cells are silicon cells made by melting several silicon crystals instead of forming a block and cutting wafers. Melted silicon molecules are re-fused into the panel. Polycrystalline cells are cheaper than monocrystalline cells but less efficient. They are blue, like SolarWorld solar panels.

Finally, amorphous silicon cells produce flexible thin film solar panel materials. Amorphous silicon cells are connected to glass, plastic, or metal substrates. Thin film solar panels are bendable and slim because of this. Amorphous solar cells are inefficient but versatile. US-based First Solar makes thin-film panels.

After making the individual solar cell, solar panel manufacturers connect the electrical connections, coat the cells with an anti-reflective coating, and encase the system in metal and glass.

QuestGreens provides top solar panel manufacturers and installation

Installing a home solar photovoltaic system is the best option for homeowners to save money and reduce fossil fuel pollution. Shop on Questgreens Solar Marketplace to discover the appropriate solar system at the right price.

Share

Share

Tweet

Tweet

Share

Share

Flip

Flip

Email

Email

Watch latest videos

Subscribe and Follow

Get a daily dose of Indianapolis Post news through our daily email, its complimentary and keeps you fully up to date with world and business news as well.

News RELEASES

Publish news of your business, community or sports group, personnel appointments, major event and more by submitting a news release to Indianapolis Post.

More InformationBusiness

SectionRussia among 4 systemic risk countries for Italian banks

MILAN, Italy: Italian regulators have flagged four non-EU countries—including Russia—as carrying systemic financial risk for domestic...

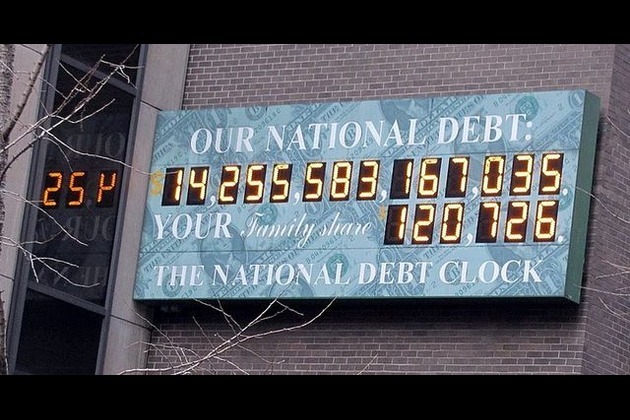

US debt limit raised, but spending bill fuels fiscal concerns

NEW YORK CITY, New York: With just weeks to spare before a potential government default, U.S. lawmakers passed a sweeping tax and spending...

Shein hit with 40 million euro fine in France over deceptive discounts

PARIS, France: Fast-fashion giant Shein has been fined 40 million euros by France's antitrust authority over deceptive discount practices...

Meta hires SSI CEO Gross as AI race intensifies among tech giants

PALO ALTO/TEL AVIV: The battle for top AI talent has claimed another high-profile casualty—this time at Safe Superintelligence (SSI),...

Engine defect prompts Nissan to recall over 443,000 vehicles

FRANKLIN, Tennessee: Hundreds of thousands of Nissan and Infiniti vehicles are being recalled across the United States due to a potential...

Microsoft trims jobs to manage soaring AI infrastructure costs

REDMOND, Washington: Microsoft is the latest tech giant to announce significant job cuts, as the financial strain of building next-generation...

International

SectionWeapons pause by Trump signals shift away from foreign wars

WASHINGTON, D.C.: President Donald Trump is drawing praise from his core supporters after halting key arms shipments to Ukraine, a...

Moscow removes Taliban from banned list, grants official status

MOSCOW, Russia: This week, Russia became the first country to officially recognize the Taliban as the government of Afghanistan since...

Netanyahu vows 'No Hamas' in postwar Gaza amid peace talks

CAIRO, Egypt: This week, both Hamas and Israel shared their views ahead of expected peace talks about a new U.S.-backed ceasefire plan....

US sends message by publicizing visa ban on UK punk-rap band

WASHINGTON, D.C.: The Trump administration has made public a visa decision that would usually be kept private. It did this to send...

Tragedy in Spain: Diogo Jota and his brother die in car accident

MADRID, Spain: Liverpool footballer Diogo Jota and his younger brother, André Silva, have died in a car accident in Spain. Spanish...

Early heatwave grips Europe, leaving 8 dead and nations on alert

LONDON, U.K.: An unrelenting heatwave sweeping across Europe has pushed early summer temperatures to historic highs, triggering deadly...